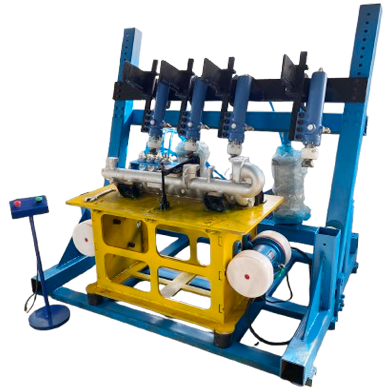

01. Brief Introduction

The core (sand) remover is a special equipment that uses a jar hammer to use pneumatic impact to perform high-frequency vibration strikes on various casting processes such as engine cylinder blocks, cylinder heads, exhaust pipes, pump bodies, valve bodies, pipe fittings, shell parts, etc. made of aluminum alloy, gray iron, etc., thereby removing the core sand from the inner cavity. Customized according to different product types

02. Basic principles

Impact vibration is used to make the workpiece produce impact acceleration and cavity resonance, and peeling stress is generated in the sand layer or the interface between the two phases to achieve the sand removal process effect. (This device uses a special high-frequency core-removing hammer, which is different from ordinary electric picks and pneumatic picks.)

03. Equipment features:

√1、 CXJ-800 automatic vibration sand removal production line adopts multi-station vibration sand removal, can work continuously, has high production efficiency, low energy consumption, and effectively reduces the labor intensity of operators.

√2、 During the working process, the equipment uses two-dimensional motion while striking the workpiece, constantly rotating and swinging the workpiece, pour out the loosened core sand to improve the sand removal process effect. Or use one-dimensional motion to vibrate and shake the workpiece with complex inner cavity, and use large amplitude and strong vibration to remove the loose core sand.

√3、 One-click cleaning of single items, high degree of automation and reduced labor.

√4、 Use multiple hammers to impact and vibrate the workpiece, increase the impact force, and ensure the effect of sand removal.

√5、Collect the cleaned waste sand and transport it to the designated location.

√6、 PLC program control is adopted to realize the interlocking and interlocking of each working step, which is safe and reliable.

√7、 The equipment adopts a closed structure to effectively isolate noise and reduce dust emission. It is also equipped with dust exhaust and dust removal systems to meet the environmental protection requirements of enterprises.

√8、 Compact structure and small footprint

√9、 Size can be customized according to product size